Project Description

The Sydney Olympic Park Complex is served by a comprehensive storm water drainage system that covers all road, parkland and building drainage needs for the site. Apart from the system serving the Newington area, the storm water drainage system is relatively new being completed during the late 1990’s.

This project emerged after investigation by SOPA found that the network had suffered significant damage during construction of the park site, as well as the detection of a number of other defects that had not been identified prior to handover.

SOPA contracts involve the remediation of the storm water system which is constructed from concrete pipe ranging from 300mm to 1800mm diameter and some large box culvert sections.

SOPA was concerned that soil would infiltrate the storm water drains through the fractures that had been detected, all of which extended right through the walls of the pipe and in some cases exceeded 25mm in width. Pipe lifting holes that were not plugged and posed a risk of soil ingress. Defective cut-ins had exposed reinforcing steel that needed to be protected.

Downer PipeTech was engaged to undertake the necessary repair works to restore the structural integrity of damaged pipes and to prevent the ingress of the surrounding backfill material into the pipelines which could result in subsidence of the surface.

The scope of works included:

- Pipe cleaning;

- Re-survey of the storm water system and condition assessment reporting identifying defects;

- Submission of a repair plan to SOPA; and

- Final repair

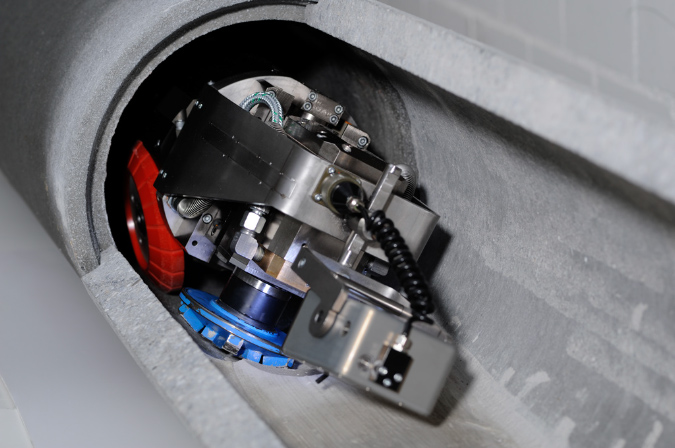

Downer PipeTech pipeline robotics unit was used to prepare and complete full structural repairs on the defects. Three repair methodologies were used:

- Man entry for greater than 800mm diameter pipe using cementitious and epoxy repair material

- Robot applied epoxy injection for sealing of junctions and pipe defects

- Point-Lining® for the repair of cracks, fragmentation, leakage, broken joints, capping off disused junctions, defective liner installations and corrosion.

Downer PipeTech has been awarded back to back contracts at SOPA over several years and have completed hundreds of repairs across the stormwater network. This ongoing work is evidence of the quality of the finished products and workmanship provided by Downer PipeTech and our range of rehabilitation solutions.