Project Description

Downer PipeTech offer Pressure lining (formerly Swagelining™) as a rehabilitation process for the renewal of pressure and non-pressure pipelines in water, sewer and industrial applications. This is the second project for SA Water having also completed a pilot project in Adelaide in 2007, which confirmed the suitability of our Pressure lining technology for the Muller Road application.

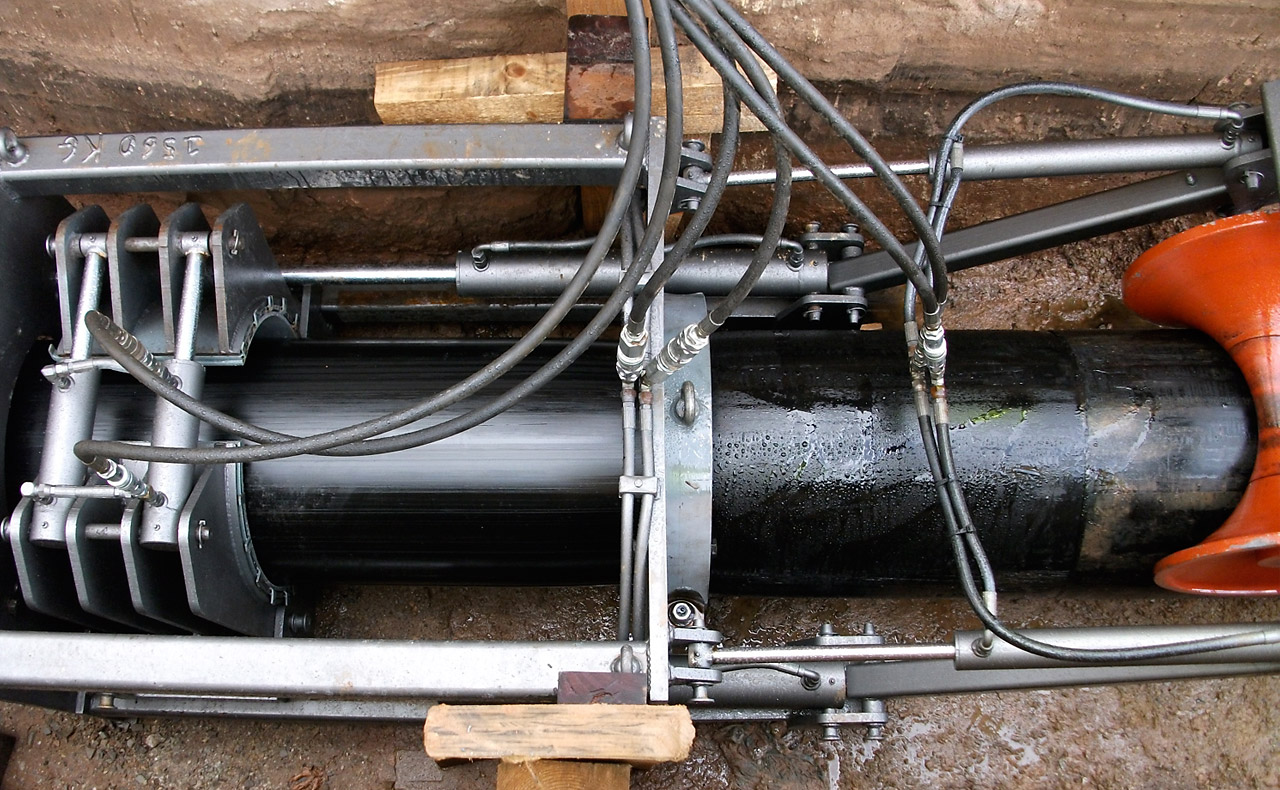

Pressure lining uses PE pipe, which has an outside diameter slightly larger than the ID of the pipe to be rehabilitated. After sections of PE pipe are butt fused together to form a continuous string, the PE pipe is pulled through a reducing dye to temporarily reduce diameter. This allows the PE pipe to be easily pulled through the host pipe. After the PE pipe is inserted, the pulling force is removed, allowing the PE pipe to return naturally to tightly fit within the host pipe. The lined pipe results in a flow capacity close to the original pipeline performance due to the excellent flow characteristics of the PE pipe. This technology is suitable for applications ranging in diameter from 150mm up to 1500mm.

This project involved the rehabilitation of an existing DN600 MSCL locking bar trunk water pipeline and is the first project of its kind undertaken in Australia. This pipeline runs beneath one of Adelaide’s busiest roads, and utilising the Downer PipeTech’s Pressure lining technology has resulted in a significant reduction in the impact and disruption to the community and environment. This project is a good example of where Pressure lining provided a cost effective solution that traditional techniques could not have delivered resulting in savings of many millions of dollars. This project established several world firsts in relation to Pressure lining. These included the use of a SDR11 pipe, installed through a number of long radius bends and installation runs of up to 600mtrs in a single length between pits.

The project was completed on time, on budget with zero LTI’s and zero complaints further highlighting the benefits of rehabilitation of pipelines using the Pressure lining process.